Metal lathes are one of the most versatile tools that every workshop needs to have. With its amazing capability to shape metals, lathes can be used to produce screw threads, drill holes on metal parts, knurl metal surfaces, make tapered edges, and much more. Metal lathes are indispensable tools for mechanics as they can be used to repair or even fabricate mechanical parts from scratch.

Safety First

Just like with any other piece of machinery, safety is a top priority when you are working with metal lathes. Considering that

lathes can mold metals to any shape you want, you can just imagine how powerful these machines are and the potential harm they can inflict if you are not careful. Thus, it is very important to know the basic safety measures to take when working with industrial lathes.

Remove chuck keys and wrenches

Yes, you need chuck keys and wrenches to prep the metal lathe for the work you plan to tackle. However, one of the most common causes of accidents involving lathes is simply forgetting to remove them from the lathe during operation.

Always remember to remove wrenches and chuck keys before operating the lathe. When the spindle starts spinning rapidly, the rotation is sufficient to give chuck keys and wrenches enough force to impale you as they fly off the machine.

Wear short sleeves and avoid loose clothing

One potential cause for accidents when working with metal lathes is wearing long sleeves or loose clothing. There is a risk that your clothing will unintentionally tangles with the spindle, dragging you in the process. Remove rings and watches before getting started.

Short hair is better

The risk posed by a long hair is the same as that of loose clothing – it could get tangled in the spindle or the material you are working on and drag you with it. Thus, shorter hair is better. But for those who prefer to style their hair long, it is best to tie it in a ponytail and secure it in place at the back of your head to make sure it does not interfere with your work

Familiarize yourself with the location of the emergency stop button

Knowing the location of this button and acting just in time might save you from serious injury in case something goes wrong.

Wear protective goggles for your eyes

It is unavoidable that small bits and pieces of the metal you are working on could fly off in all directions. It is best to protect eyes from these ejected materials by wearing the appropriate eyewear.

Don’t use your hands to remove metal turnings

Remember that you are working with metals here and those metal turnings can be very sharp. Thus, never use your hands to remove them. You can use a brush when cleaning.

Don’t place tools directly on the lathe ways

You might want to keep your tools handy and within easy reach. However, it is never a good thing to lay them directly on lathe ways as they might cause unforeseen accidents. It is better to use a separate table for your tools.

Steps In Using A Metal Lathe

Warm up the lathe

Without placing the workpiece yet, turn on the spindle to warm it up. For this warm-up phase, set the spindle speed to 1000 rpm and leave it on for around ten minutes. Be sure to that the machine is well-lubricated and you can use this warm up phase to get your tooling ready.

Insert a tool block

After preparing all your tools and you’re done warming up the lathe, you can now insert a tool block in to the tool holder. At this point, you need to make sure that the tool block is securely put in place. Insert the cutter into that spot in the tool block intended for it. Be sure to tighten it securely so it won’t come loose during operations. Of course, you need to make sure that the cutter is sharpened beforehand to get the best result from the lathe.

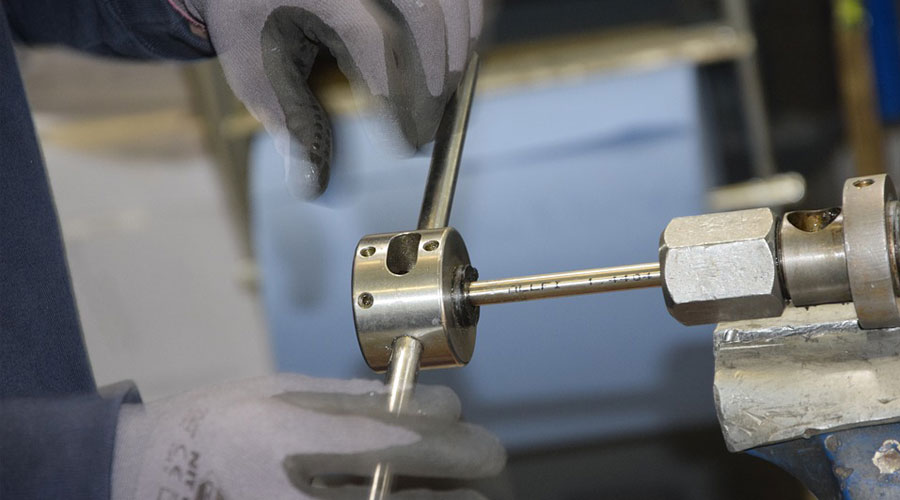

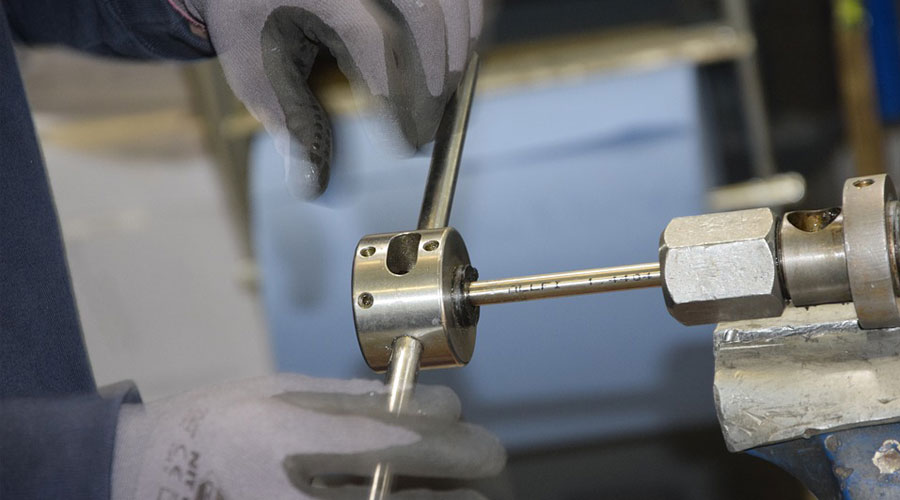

Insert a drill chuck

If the project you intend to work on requires you to drill holes into the workpiece, then you need to insert the drill chuck into the tail chuck for this purpose. You can gauge the depth of the drills by using the measuring device located at the crank at the far end.

Set the Z zero point

Before setting the zero point, you need to stop the spindle’s rotation. Move the tool holder close to the end of the workpiece. Using a 0.5-inch block as a gauge, place it between the gap of the piece and the tool tip. Adjust as needed to ensure that it fits tightly in the gap. Pull the tool towards yourself to create an X-axis and set the micrometer wheel to zero. Move it 0.5 inches towards the workpiece and this is now your Z zero point.

Set the X zero point

The next thing to do is set the X zero point. This is done by bringing to tool’s z-axis towards the spindle with the top tip pointing towards the piece. Like before, place a 0.5-inch block between the workpiece and the tooltip and make adjustments until it becomes a tight fit. Then move the tool block to the right past the piece and set the x-axis micrometer wheel to zero before turning the measuring wheel 0.5 inches away from you. This now becomes the X zero point.

After making these necessary adjustments, your

metal lathe is now ready and can be used to produce screw threads, drill holes on metal parts, knurl metal surfaces, make tapered edges. However, it may be necessary for you to be under the supervision of a more experienced machinist at first. This way, you will learn more about the finer points and techniques to use when working on a specific metal turning project.